Plastic Prototyping in India

Plastic Prototyping in India: A Tool for Innovation, Design Refinement, and Problem-Solving

Plastic Prototyping in India has become one of the most powerful tools in product development. Think of it as early-stage seed funding for your idea – a small investment that lets you turn a concept into a real, testable model long before full-scale production begins

You research, you ideate, and then you turn those ideas into something real. But there’s always a gap between what we imagine on a screen and what actually gets manufactured. This is exactly where plastic prototyping in India steps in and becomes the hero. It helps you identify issues early, validate ideas faster, and avoid expensive retakes later in the process.

A plastic prototype gives you a 3D physical sample of your product — its size, shape, aesthetics, functionality, and even how the material behaves — all before manufacturing begins.

Let’s keep it simple: Plastic prototyping in India allows you to touch, test, and evaluate your imagination in real life.

Why Is Plastic Prototyping in India Important?

Because this early-stage prototype saves you from major design and production disasters. By the time you reach manufacturing, you already know what works and what doesn’t hence giving you complete freedom to refine, adjust, or even redesign your product without incurring financial losses and identity crisis.

It becomes a powerful decision-making tool. One glance at your prototype can define the entire direction of your product.

This is why industries such as consumer electronics, automotive, medical devices, packaging, and FMCG increasingly rely on plastic prototyping in India. It reduces production errors, speeds up development cycles, and enables brands to launch high-quality products faster.

For once, trial and error actually works — and works in your favor.

How Does Plastic Prototyping in India Work?

What blows my mind is the range of techniques it offers. Depending on your design, purpose, and budget, plastic prototyping in India can be done using different methods, each with its own strengths.

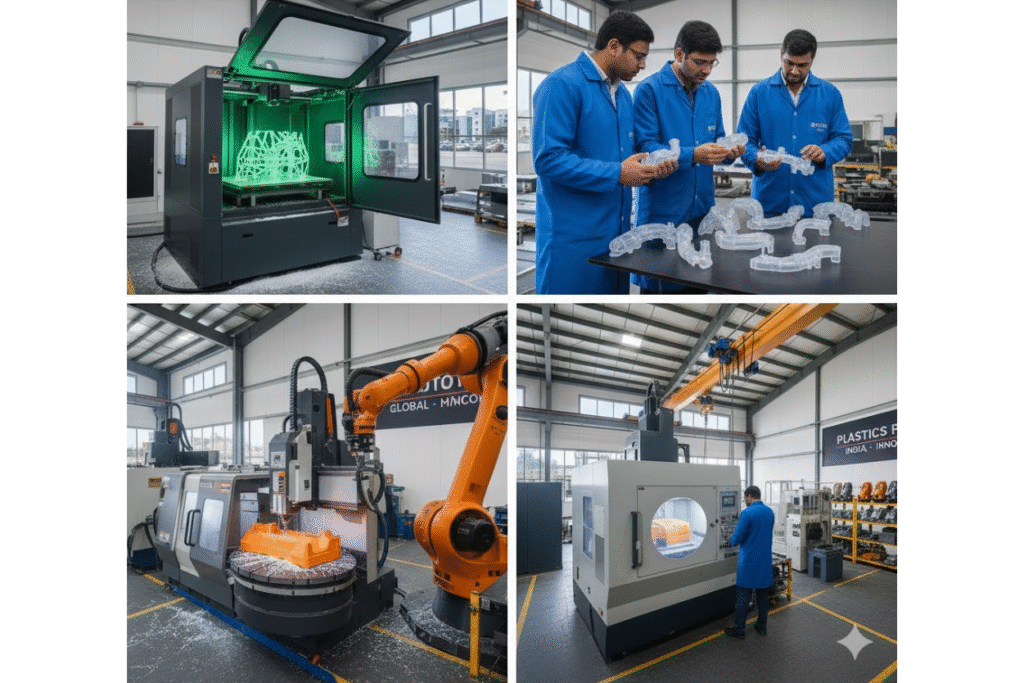

3D Printing (Additive Manufacturing)

Ideal for rapid prototyping, early-stage samples, design exploration, and functional tests.

CNC Machining

Perfect for detailed structures, and prototypes requiring strength and accuracy.

Vacuum Casting

Great for small batches of high-quality prototypes that resemble final products.

Injection Moulding for Prototypes

Used for mass-production-like samples, durability tests, and cost-effective, repeatable units. Excellent when you want to validate how your product behaves at scale. Ultimately, your use case decides the method.

Conclusion.

Plastic prototyping in India acts as your sharpest critic, guiding every stage of product development – testing, validating, and refining issues long before they become expensive mistakes